MARINE FENDER INTRODUCTION

Yangtze Maritime offers a full range of fenders to suit different application. Whether it is for new installation or replacement, we provide products with superior service life and resistance to physical and corrosive environments.

With over ten years of experience of design and manufacturing of marine fenders, Yangtze Maritime strive to consider technical and commercial benefit for our customers.

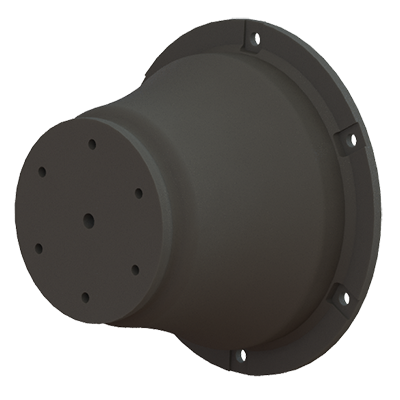

CONE FENDER

Versatile and proven in practice, cone fender is well suited to berths and terminals handling large vessels, for load sensitive structures and for berth upgrades.

◼ High efficiency

◼ Good angular performance

◼ Wide range of sizes

◼ Standard and intermediate rubber grades

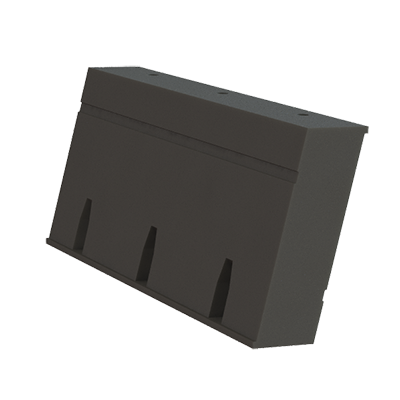

STAGHORN BOLLARD

Versatile and proven in practice, cell fenders are well suited to berths and terminals handling all vessel sizes.

◼ Well proven design

◼ High efficiency

◼ Modular design

◼ Good angular performance

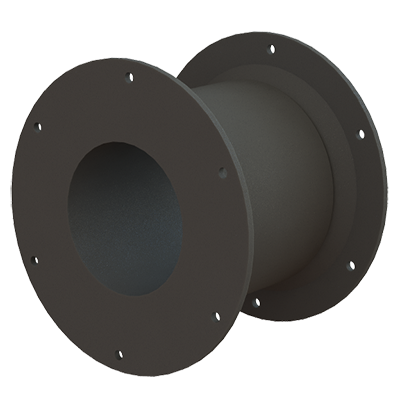

UNIT ELEMENT FENDER

Unit element fender can be used in arrays with steel panel, or in pairs with UHMW-PE shield as V-fenders. A small foot print makes Unit element fender perfect where fixing area is restricted.

◼ High efficientcy

◼ Modular design

◼ Good angular performance

◼ Wide range of sizes

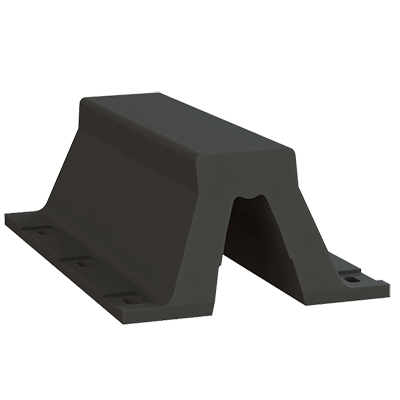

ARCH FENDER

Easy and fast to install, arch fenders are well suited to berths handling a variety of vessel types and sizes. They can be fitted vertically or horizontally to provide long lasting and low maintenance protection.

◼ Tough and reliable design

◼ Simple installation

◼ Rubber-faced designs

◼ Wide ranges of sizes and lengths

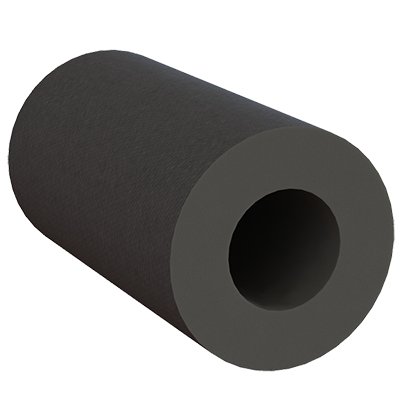

CYLINDRICAL FENDER

Popular for over 50 years, cylindrical fenders are simple and effective for a range of ships and applications. They are commonly used in areas with small tides and where low hull pressure and reaction forces are significant.

◼ Very simple design

◼ Popular and effective

◼ Easy to install

◼ Wide range of sizes

◼ Two standard compounds

D FENDER

D fenders are the commonly used rubber bumpers across the world. The flat back facilitates the easy installation of D fenders on various surfaces for the protection of ships and docks.

◼ Low profile design

◼ Reasonable reaction force and high energy absoption

◼ Easy to install and low maintenance cost

◼ Can be mounted on vessel hull